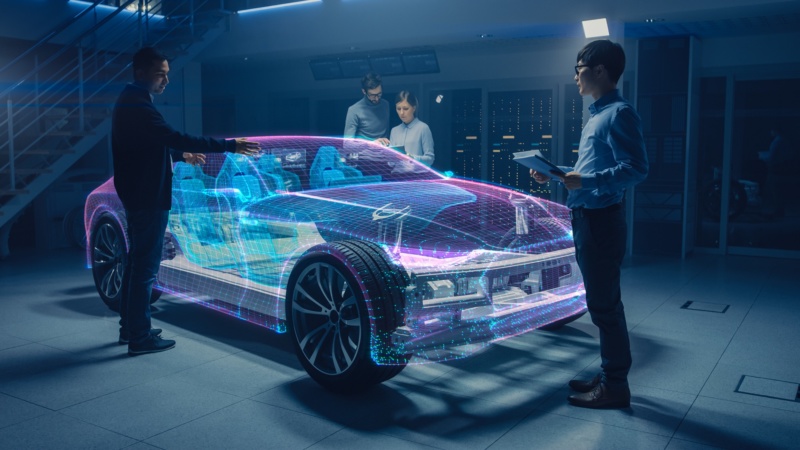

At Xi, we have a lot of experience working remotely on design and engineering projects. Many companies are having to adapt to new work practices after the Covid-19 outbreak. However, engineering work can continue as normal in this new setting. In this blog post we will share some of the tools and lessons learned over the years, helping clients to virtually test their designs

At Xi, we have vast experience in virtual prototyping by working with extremely diverse projects and clients. Our past work includes a range of simulation and design projects which vary from the acoustic performance of speakers to wind microclimate around building developments.

What is virtual prototyping and design?

Product design and development commonly involves the iterative creation, testing and subsequent modification of a physical prototype. The production of the physical prototype requires ongoing testing and modification. As a result, it can become costly and extremely time-consuming. Furthermore, access to fabrication facilities, test sites and labs often can be highly complicated, costly and currently impossible to use. However, by using numerical simulations it becomes easier and more efficient to create and test virtual prototypes.

The process of designing your virtual prototype

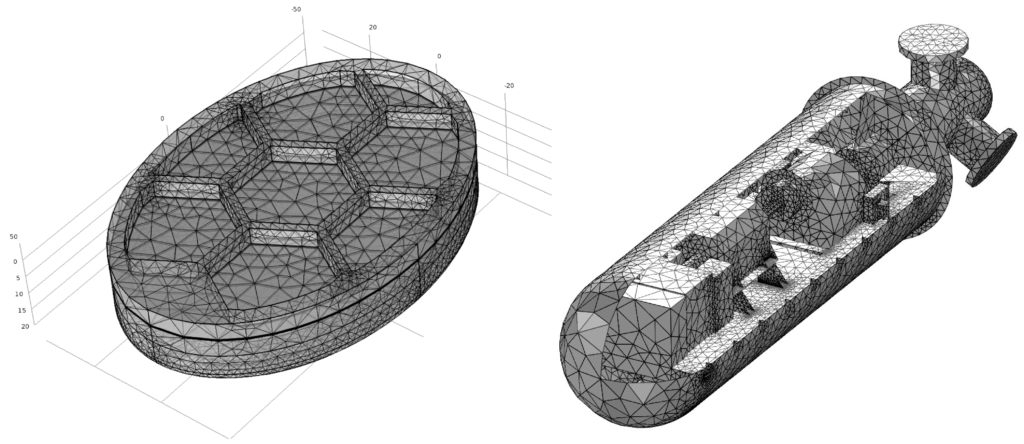

Numerical simulations can be created to represent most physical phenomena such as structural dynamics, multibody dynamics, acoustics, electrostatics, electromagnetism, fluid flow, heat transfer and all their complex coupled interactions. The typically involves the building of a model geometry based on engineering drawings or CADs provided by our client. Commonly, the client will also provide a range of materials they’d like to compare including some other design parameters such as loads, flow rates, voltages etc. We believe that communication plays a vital role in such projects. It is crucial to understand our clients’ needs to tailor and deliver the best design possible.

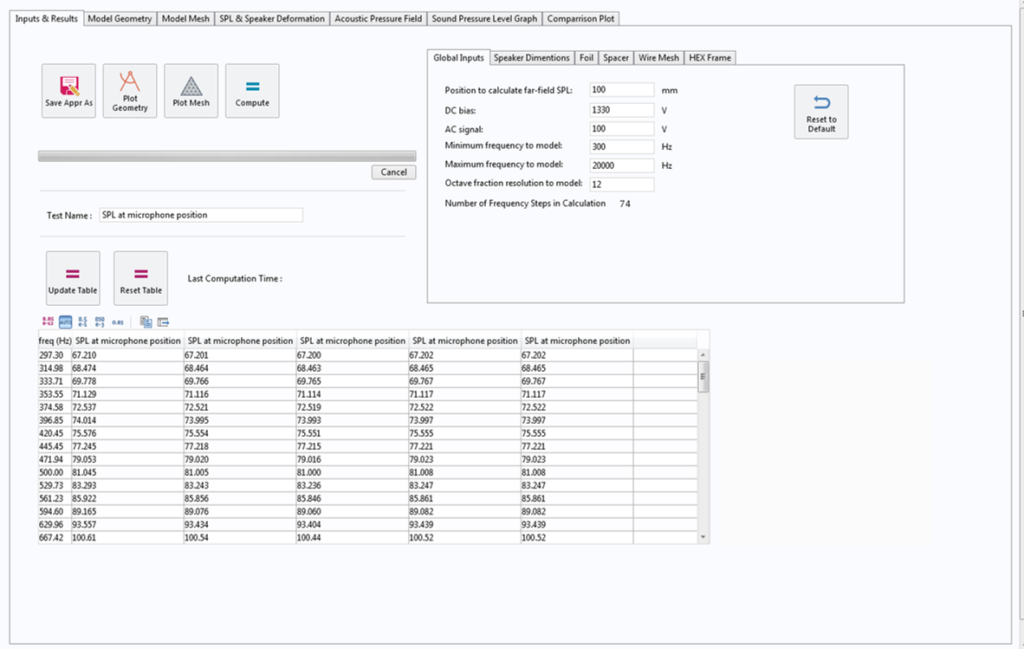

At Xi, we build models that can be easily adapted. Where possible, all the design choices are represented as single input parameters. All these parameters are linked through the model, so when we chose to vary something like a geometric dimension, the entire geometry automatically updates without the need to for time-consuming rebuilds.

Commonly at Xi, we use a call sheet which includes parameters that our client would like to test. This might be in the form of an Excel spreadsheet. For instance, someone designing a generator may use a call sheet to specify the number of magnets to be tested, the magnet size, number of windings in the coils and the air gaps between the rotor and stator;

Communication is key for a successful project.

A critical step in designing a robust simulation is to understand our client’s design goals. At Xi, we help our clients unlock the true potential of their design with numerical simulations but at the same time we also very clear about its limitations.

As part of the process, the client and our experienced modellers will decide the most cost-effective path in delivering the virtual testing programme together. An example of one of these choices may include the decision to model using a frequency domain approach or a more computational expensive time-domain approach. A good understanding between the modeller and the client is vital to make the right simulation design choices. Effective communication is the only way to test your ideas and push innovation to its very limit.

How we communicate with our clients

Effective communication can be a real challenge. As engineers we’d all love to stand around a whiteboard fleshing out ideas, but that this is not always possible. Over the years we shifted from one to one meetings to video conferences. Initially, we made this move to reduce the cost and time related to travel. Furthermore, we actively wanted to reduce our contribution to greenhouse gas emissions. Although our working life has now changed due to COVID-19 outbreak, our working pattern has stayed the same since we have been embracing remote working for years.

We use various software for conference calls which are very effective for screen sharing. Although we use some more often than others, we are very flexible to adjust to our clients’ needs when necessary. Our team is always happy to comply with any systems that you might use. Some important lessons that we have learned while teleconferencing and webcasting:

- Set up your app early and test it. Struggling with setting up a conference call is very common. Doing it in front of a prospective client can be stressful.

- Have a tidy desktop and prepare your documents in advance. It’s important to avoid “oversharing”. Remember that the names of icons/short cuts on your desktop can reveal information about other clients and sensitive projects you may be working on.

What tools do we use for simulation?

We have a series of large modelling computers at our office in central Edinburgh. These computers do the heavy lifting for the finite element models used for virtual prototyping. We use remote desktop technology to remotely access these computers whether we are in the Edinburgh office, at a client’s workplace or working from home due to COVID-19 developments. The period of social distancing has had very little effect on our productivity with respect to numerical simulation and data processing. These are some of the core software we use at Xi for advanced modelling and simulation:

- COMSOL Multiphysics

- NoiseMap

- Matlab

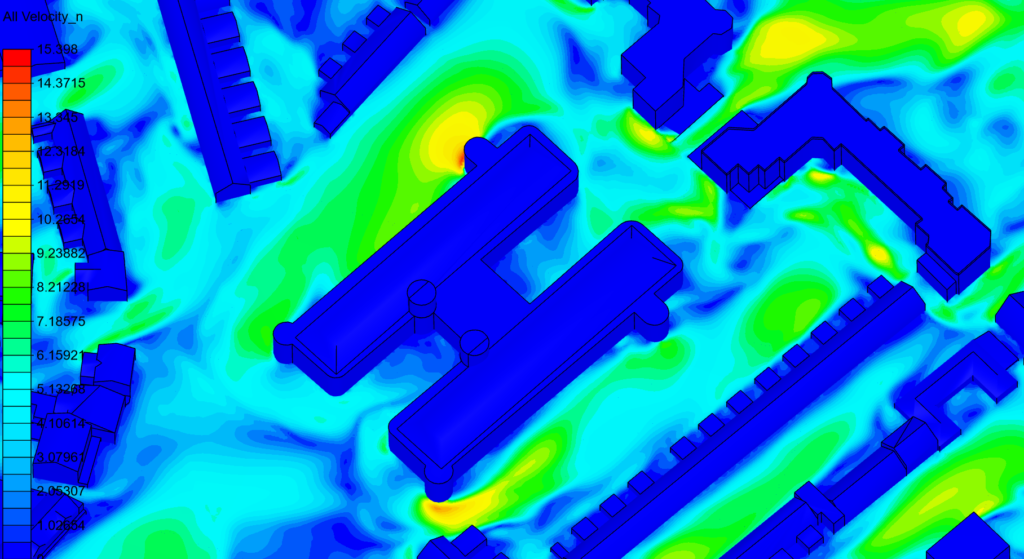

We also use modelling software that is accessed and run on third-party’s servers. In these cases, we use browser applications to access the server remotely to load and run our models. An example is SimScale. At Xi, we often design simulations to assess pedestrian comfort & safety issues which might derive by new developments as a result of the change in wind microclimate.

SimScale allows us to produce accurate CFD models using advanced modelling & simulation by accessing it through their servers.

Why use Xi on your next project?

Virtual prototyping and remote communication are both vital tools that can maintain product design during this difficult time. We can help you keep your project moving forward while fabrication and physical testing might not be possible. By engaging with Xi’s engineers, you can also increase the productivity of your teams who may be under-utilized. At Xi, that act as a front end to our simulations. Xi can develop simulations which provide a GUI front-end which can then be issued to your engineering team.

Then your team can conduct their virtual testing in house. For more information please don’t hesitate to contact our team. We are always happy to talk about exciting new projects and find ways to unlock their true potentials.